Executive Summary

California Tower is a mixed-use development located in Northern California. The facility consists of 56 stories residential tower, 9 stories podium with 3 stories of a below-grade parking garage. Designed by HKS Architects, Inc. and OMA, the size of the residential tower is approximately 882,462 square feet and soars 592 feet. The construction of California Tower starts in Spring 2016 and is estimated to finish by Spring 2019. The project delivery method divides into two sections. The core and shell of the building follow design-bid-build contract, while the mechanical, electrical, and plumbing (MEP) system utilizes design-build contract. By the end of the construction, the building is hoping to get LEED Silver certification.

California Tower existing structural systems features 10-inch thick reinforced concrete flat slabs for below grade, 15-inch-thick reinforced concrete flat slab for B1 floor diaphragm and 8-inch-thick post-tensioned concrete flat plate for typical residential units. The main lateral system consists of coupled special concrete structural shear walls. The building is also supplemented by wing walls at the lower levels to enhance the overall stability of the tower. The coupling is provided by either diagonally reinforced coupling beams or steel-reinforced composite steel coupling beams.

Based on the complexity of the building both architecturally and structurally, a meticulous analysis is required to understand how the structure behaves under both gravity and lateral loads. To achieve this, structural analysis has been done in notebook submissions throughout the semester that explores the system's compliance and adequacy to design codes.

The results of this investigation have resulted in the proposed design to optimize the lateral system. One of the disadvantages of using diagonally reinforced coupling beams is the complexity of the detailing required that will increase the construction time and costs. Furthermore, special inspection is required to make sure that the concrete bonds properly with mild steels. Due to these potential problems, the proposed design utilizes the use of Viscoelastic Coupling Damper (VCD) to improve building's performance under lateral load. The gravity system will be post-tensioned flat slabs. To understand the feasibility of this design alternative, a cost analysis will be performed and compared to the existing design. Facade studies will also be done to evaluate the thermal, moisture, and structural performance.

Depth Topic

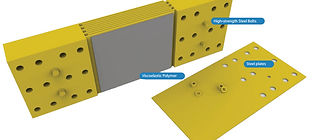

One of the popular catchphrases in the AEC industry is resiliency. A resilient building is a building that can recover from the disaster within a short period of time. During the disastrous event (e.g. earthquake), the biggest casualties might not be caused by structural failures, but economic losses due to the extensive damages. To improve the resiliency of the building, the proposed design is to use VCD in the building. VCD is composed of multi-layered viscoelastic materials enclosed between layers of steel plate which are anchored at the alternating ends of the shear walls.

Under lateral load, the viscoelastic material undergoes shear deformation that develops both a velocity-dependent viscous force and a displacement-dependent elastic restoring force that increases the damping and stiffness of the overall system.

The building's performance that includes, but not limited to comparisons of interstory drifts, story acceleration, base shear, and base moment will be observed between the normal coupling beam and VCD coupling beam systems. Optimization of the design by varying the number of VCD coupling beam used in the building will also be performed.

Proposal

Breadth Topics

Construction Breadth

In order to fully analyze the feasibility of the design alternative, a cost and schedule analysis will be performed and compared to the existing structural system. The detailed cost estimate will be based on 2017 RS means or product cut sheets.

Enclosure Breadth

The existing enclosure is composed of unitized curtain wall system where each curtain wall unit is stacked on top of each other. Building enclosure is not only important in protecting occupants from the external weather but also to ensure the efficiency of the building performance (i.e. indoor air quality, thermal, mechanical, and energy). Thus, this breadth is to highlight the importance of standardized testing by creating a process flow chart that will help the engineer to determine types of testing and required documentations to ensure the performance of the building enclosure.

MAE Requirements

The proposed design will require modeling of the lateral elements. This topic was covered in AE 530 Computer Modeling of Building Structures. Additionally, the alternative design will also be based on seismic requirements stated in ASCE 7-10 and PEER TBI. All the seismic concepts and calculations will be based on AE 538 Earthquake Engineering and Design.